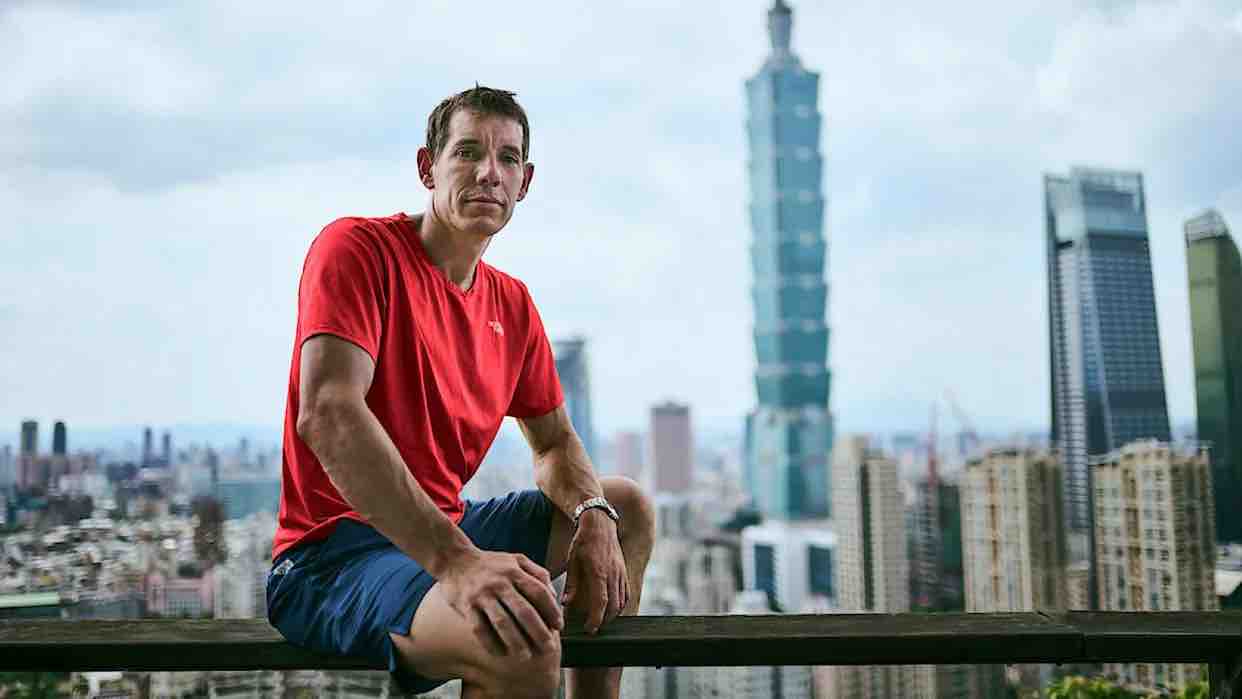

This past week, outdoor enthusiasts—including our team here at BuonX—have been captivated by the record-breaking urban free solo performed by world-renowned climber Alex Honnold.

The world tuned in not just to witness Honnold became the first person to free-solo the 508-meter (1,667-foot) Taipei 101 skyscraper, what was once the tallest building on Earth—Taipei 101 (surpassed by the Burj Khalifa in 2009.)

Did you know that beyond biotech and chips, the functional textiles in Taiwan is also famous worldwide? Alex Honnold’s life relied on this Taiwanese superpower--- his shoes from La Sportiva are also Made in Taiwan.

The Evolution of an Manufacturing

In the 1970s, Taiwan entered a "Golden Era" of synthetic textiles, becoming one of the world's top four exporters alongside Hong Kong, Italy, and South Korea. At its peak, textiles accounted for nearly 40% of Taiwan’s total exports during Taiwan's economic boom in the 80s.

By the 1990s, rising labor costs and environmental awareness pushed manufacturing toward China and Southeast Asia. However, the industry didn't vanish like most of its peers; it evolved. Most companies kept their R&D hubs in Taiwan, and by the 2000s, they had successfully rebranded as specialists in technical and functional textiles. Today, elite brands like Adidas, Nike, Lululemon, Under Armour, and Patagonia depend on the innovation from these labs on the small island.

Aside from the better known suppliers like Eclat (儒鴻) and Far Eastern New Century (遠東新) there are also many other smaller suppliers to fulfil every requests.

Currently, over 70% of global functional fabrics (waterproof, moisture-wicking, fire-resistant) incorporate Taiwanese technology. For instance, Taiwan-based manufacturers produce over 60% of Nike’s athletic shoes globally.

Why the Global Supply Chain Still Pivots on Taiwan

Taiwan has a sustainable presence on the global stage as well as participating in international events like the FIFA World Cup and the Olympic Games with its fabrics due to three distinct advantages in its textile industry:

-

Smart Textile Innovation: Recent breakthroughs include "intelligent fabrics" with embedded sensors that monitor muscle activity and vital signs, with its semiconductor industry can be just minutes away (literally) Taiwan retains its irreplaceable position in wearable technology.

-

Geographical Proximity & Clustering: The island’s density is its strength. While logistics from Austin to Phoenix would take a full day if not more, transporting components from the northernmost tip of Taiwan to the southernmost hub takes only 2–3 hours. This hyper-efficient cluster accelerates prototyping and production.

-

R&D and PFAS-Free Chemistry: As U.S. regulations tighten on "Forever Chemicals," many global suppliers are struggling. Taiwan’s textile labs are pioneering Bio-based Nylon and PFAS-free DWR (Durable Water Repellent) treatments that meet the most stringent ESG standards without sacrificing performance the product needed.

The Insight for 2026

As the U.S.-Taiwan Trade Agreement gains momentum, it’s time to look beyond semiconductor. Audit your supply chain for durability, sustainability, and strategy, Taiwan might be an unthinkable but cannot be missed option!

What is your #1 bottleneck in expanding your supply chain right now?

For more Asian insights, follow BuonX Consultancy founder Betty on LinkedIn.

Ready to embark on your sustainable supply chain? Join BuonX Consultancy in turning vision into daily practice. Contact us today.